Rethinking neck protection in hockey

Brynn Broaddus and 15 of her peers spent spring break developing advanced neck protection to improve hockey players’ safety on the ice in collaboration with the Pittsburgh Penguins and Covestro.

She could have traveled home to spend time with family or hopped on a plane to relax in the sun, but Brynn Broaddus, along with 15 of her peers, opted to spend spring break developing innovative prototypes of hockey equipment to make the sport safer.

In its seventh year, Rethink the Rink, an initiative between Carnegie Mellon University, Covestro, and the Pittsburgh Penguins, focused students’ efforts on improving the equipment players wear to protect their necks from skate blades. Following the tragic passing of former Pittsburgh Penguin Adam Johnson in October 2023, more hockey teams and leagues have mandated that players utilize neck protection on the ice.

Rethink the Rink participants have one week to ideate solutions, develop and test prototypes, and create a compelling presentation to explain their concepts to a panel of expert judges from the Penguins, Covestro, Bauer Hockey, and CMU’s College of Engineering.

Broaddus, a first-year student studying mechanical engineering, applied to be a part of the initiative because she wanted to learn more about her major in the real world.

Tyler Kennedy, former Pittsburgh Penguin, presenting about the current-state of neck guards.

“When the week kicked off we heard from experts in materials, medicine, and hockey,” Broaddus said. “We got to hear firsthand from former Penguin Tyler Kennedy what players really want on the ice. That was helpful when it came time to create our design and start building.”

Students divide themselves into four teams based on experience (graduate year and major) and self-identified strengths (fabricating/building, analysis/computation, leadership/project management, and presentation/communication). Though it might sound like a competitive environment, Broaddus shared that the teams are very supportive of one another as they share a common goal—to beat the clock.

“We had to really challenge ourselves to build and test a prototype in such a short period of time,” she said.

Throughout the prototyping process Broaddus surprised herself by how much she had to learn.

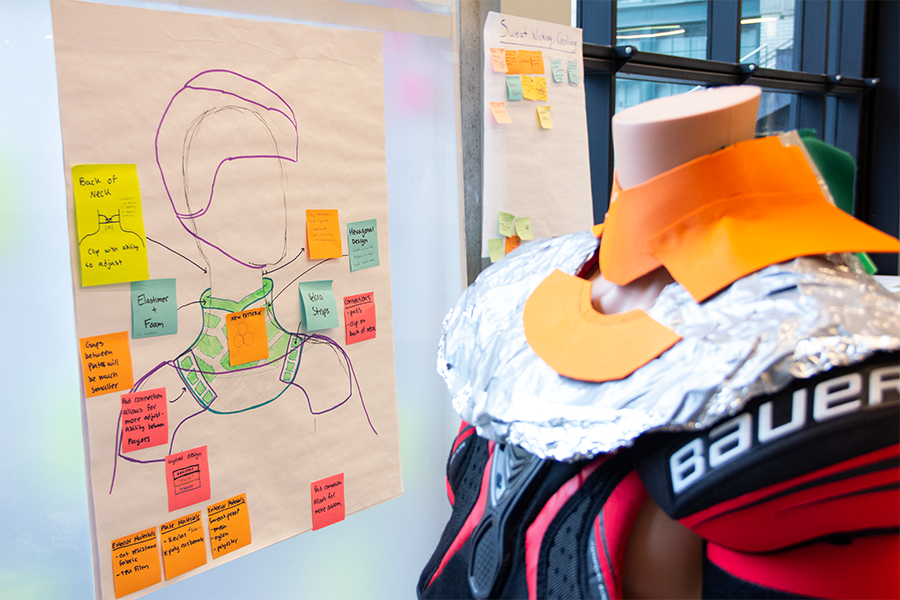

“Initially, I thought we’d work with the exact materials we needed to make our equipment, but that wasn’t the case. We had to build the shape with plasric wrap, foil, and cardboard before we could plug in the appropriate materials. We even had to learn how to sew!”

Because the project isn’t only about developing equipment for professional hockey players, Broaddus’ team had to figure out what materials they could use to create equipment that could grow with younger players and be washed with the rest of a family’s laundry.

Her team’s final prototype impressed the judges, and the group took home the award for Best Prototype.

“It feels really good to be recognized,” Broaddus said. “But at the end of the day what matters is players’ safety. Safety equipment doesn’t work unless players wear it, and I think that my team, and the other teams, tried our best to make the equipment not just as safe as possible but as comfortable as possible too. That way we could make something players would want to wear and maybe even save a life.”

We hoped to make something players would want to wear to maybe even save a life.

Brynn Broaddus, First-year student, Mechanical Engineering

Congratulations to all participants. The winners this year included:

- Best Overall: Fangchen Chen, Luca Garlati, Misal Bhalala, Vedant Singh

- Most Innovative: Abigail Beyene, Jessica Wu, Ricky Castro, Roman Kapur

- Best Prototype: Brynn Broaddus, Isaac Osei, Jiin Jeong, Sushanth Gundumalle

- Participation: Bing Bi, Katherene Qi, Tiffany Yang, Zhuoyi Zou